The oil and gas industry demands bearings that can withstand extreme operating conditions, including heavy loads, high temperatures, and corrosive environments. Bearings used in drilling rigs must offer exceptional durability, reliability, and resistance to wear and tear. They are engineered to perform under high pressure, ensuring smooth operation even in the harshest conditions. Additionally, these bearings require minimal maintenance and have a long service life to reduce downtime and operational costs. Precision and quality are crucial, as any failure can lead to significant financial and safety risks in offshore and onshore drilling operations.

At HSN, we provide robust and high-quality bearing solutions specifically designed for the demanding conditions of oil drilling platforms. Manufactured from premium materials and enhanced by advanced heat treatment processes, our bearings deliver exceptional durability and performance. We cover most world-famous oilfield equipment brands, ensuring compatibility and reliability. With abundant inventory, we guarantee quick and efficient delivery, keeping your operations running smoothly without interruption.

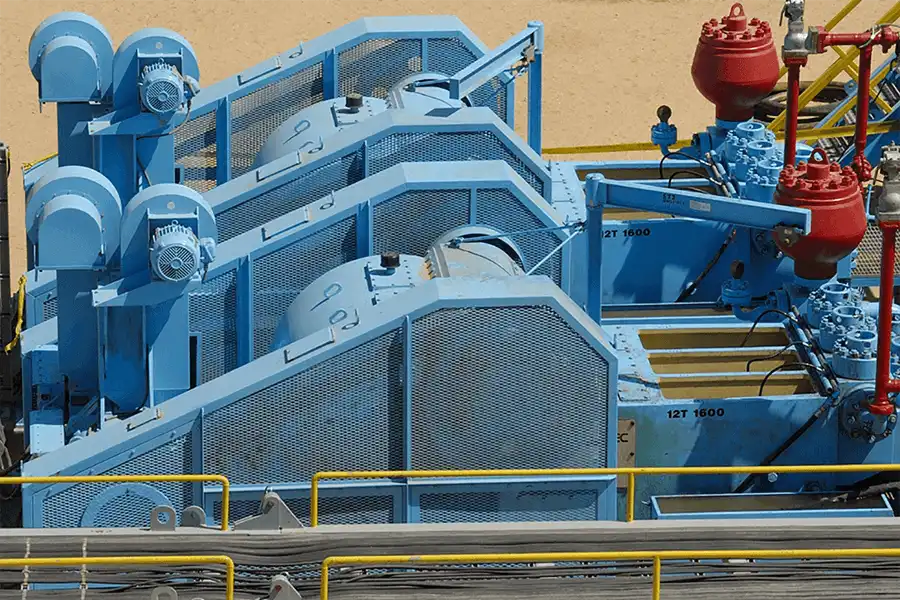

The mud pump supplies the drilling rig with a constant flow of high-pressure mud (drilling fluid). These positive displacement pumps operate up to 10,000 psi resulting in high radial loads at the typical bearing positions including the crosshead bearings, eccentric bearings, crankshaft main bearings and driveshaft bearings.

Sheaves are used in crown and travelling blocks as well as in heave compensation systems. It requests reliability under high static and dynamic loads to ensure maximum uptime under the extreme range of drilling conditions.

The top drive / swivel supports the weight of the drill string, while simultaneously acting as a rotating passage way to permit drilling mud to flow into the drill string. The top drive, additionally, provides the torsional force needed to turn the drill string. This application requires high reliability and resistance shock loads generated during the drilling process.

The primary function of the drawworks is to raise or lower the drill string and provide proper weight on bit. Modern drawworks and winches also can operate active heave compensation, designed to compensate for the wave motions on floating rigs. The resulting rapid load cycles require an extremely rigid system.

The rotary table is the traditional solution for providing the rotational force to turn the drill string. Their bearings are found in the main and drive shafts, upper and lower, to accommodate high radial as well as axial loads.